Know-how

SMCF INDUSTRIELLE specialises in the planning and manufacture of injection moulds for seals made of rubber materials and, in particular, for seals in vehicles (cars, HGVs, special vehicles, rail vehicles...).

With its high-performance fleet of machinery, SMCF INDUSTRIELLE manufactures high-precision moulds with complex geometries, optimised casting positions and high-quality mould closure.

Thanks to the over 20 years of experience of planning and manufacture enjoyed by its staff, SMCF INDUSTRIELLE can offer every individual customer first class technical knowhow as well as superb solutions and concepts.

Due to its work in many different sectors, such as automotive, rail and special vehicle constructions, customers of SMCF INDUSTRIELLE can benefit from its wealth of experience every day.

When designing injection moulds, SMCF INDUSTRIELLE cooperates constructively with its customers.

Quality Policy

To guarantee the quality of the injection moulds and ensure the trust and satisfaction of customers, SMCF INDUSTRIELLE pursues a quality strategy with the aim of supplying the moulds according to the specifications and on time and at fair prices.

In the awareness of the importance and the advantages of this way of working, SMCF INDUSTRIELLE has introduced a strict quality system.

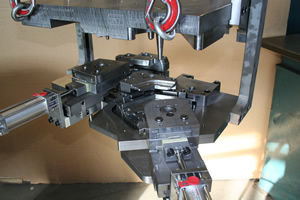

Dimensional control of the moulds

Using the suitability control of the production materials in conjunction with powerful testing equipment, SMCF INDUSTRIELLE can manufacture high-precision moulds with a complex geometry.

The company has been able to attract highly-qualified staff with extensive experience in moulding rubber parts who can ideally control the material flow in the moulds.

Basic data

- SMCF INDUSTRIELLE has expertise with over 20 years of experience in the planning and manufacture of moulds for sealing parts made of rubber:

- Injection moulds with regulated heating channel system,

- Injection moulds with electric heating rods.

- The moulds are mainly destined for the manufacture of rubber parts and sealing applications (doors, flaps...) in the motor sector.

- In-depth knowledge about the material flow in the moulds and with respect to the use of EPDM or thermoplastics.

- SMCF INDUSTRIELLE can ideally control the two main factors – the closure of the moulds and casting positioning.

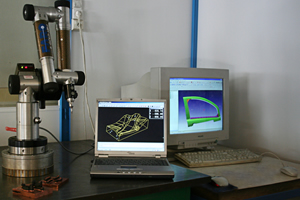

- Development and planning department with 5 CAD workstations with the Think Design 3D software and Catia V5 interface.

- Planning and development of moulds for rubber parts with prototyping in cooperation with customers.

- In-depth knowledge of the structure and mechanics of moulds, from removal from the mould with reverse taper, minimal casting seams and barely visible divisions.

- External dimensions of moulds up to 1,000 mm x 800 mm possible (upon request).

- Moulds are manufactured with very low tolerances of 2/100.

- All moulds manufactured are supplied with a control report.

- Process with repetition precision for mould cavities, tolerances of 1/100 to 2/100 to be observed and seals...

- Production monitoring with OpenMind CAM software (hyper mill).

- Parts checked with 3D testing equipment.